High Speed Imaging Solutions for Laser Copper Welding

In recent years, methods for copper laser welding has attracted the attention of engineers of energy efficient vehicles. Components of these vehicles, including motors and batteries, are made of highly conductive copper, and laser welding is a key process for copper material processing.

To meet the demands of this industry, NAC introduces the advantage of visualizing laser welding of copper with high-speed cameras, as well as the shooting techniques and key points to consider when taking images.

Key Considerations for Copper Laser Welding

Copper is a highly reflective material, consequently, welding with an ordinary use of near-infrared laser tends to produce 'spatter', which produces defects as a result. To reduce spatter, the following research findings have been understood through high-speed image visualization.

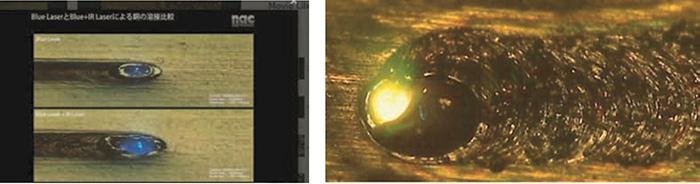

- Welding with visible wavelength lasers such as Blue and Green as those wavelengths of light are easily absorbed by copper, which works to reduce spatter significantly

- Welding using a hybrid of visible and IR wavelengths

- Welding using a dual-core laser to adjust laser intensity level for the center/corner of the laser

- Welding using wobbling technique with a scanner

- Other new laser welding technologies

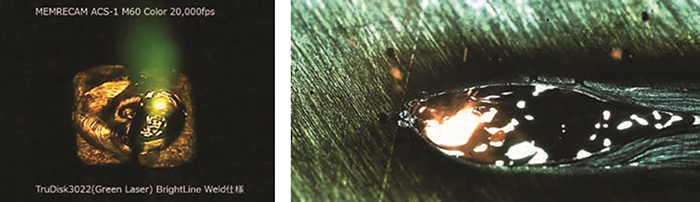

Green Laser Welding

Courtesy of Laserline GmbH

Advanced Welding Research with High Speed Cameras

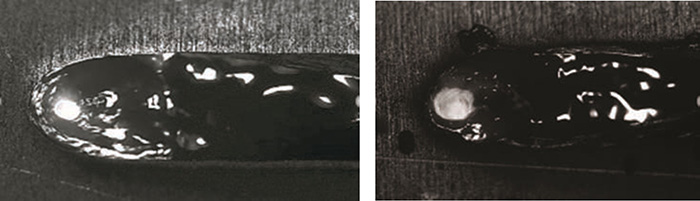

By shooting with a high-speed camera, you can observe the instance of spatter generation. In addition, you can visualize flow in the molten pool, solidification timing and other various factors that lead to the spatter generation in detail.

Welding quality is usually analyzed from the visual inspection to check the formation of the welded material and the cross-section of the welding. Slow motion images during welding allows you to analyze these instances in great detail and make comparisons across different parameters including material type, shape, plate thickness, laser output, focusing condition, and feeding rate. High speed image analysis allows for the observations of minute detail across conditions allowing for optimization welding techniques.

Keys for brilliant high-speed imaging

Filter Selection:

There are various types and wavelength of welding lasers such as IR, Green, Blue, and hybrids of IR and visible wavelengths. If the laser light from weld laser is reflected by the base metal and light reflected in the shooting image, the welder can miss the observation points e.g. molten point, as a result. Therefore, it is necessary to remove the effect of reflection of laser light by adopting various filters such as short-pass filters, certain wavelength cut filters, bandpass filters, and notch filters that optimally cut the target wavelength.

Blue and Green Laser Welding

Courtesy of Laserline GmbH | Courtesy of TRUMPF Inc.

Camera position/viewing angle:

In laser welding, camera positioning is critical to key observation area viewing. For example, if you want to visualize the inside of a keyhole, it requires an upright camera setup that overlooks the target from the top. Further, if you want to visualize the rippling of the hot water surface or the scattering of spatters, it requires to setup camera view angle near the horizontal axis to enables phenomena capture in more detail. In this way, setting up the high-speed camera according to the target object and factors to be observed is also a key consideration.

Support for Magnified Shooting:

For thinner laser welding, e.g. 5mm bead width, higher magnification optics are required. If the optical magnification ratio becomes higher, the relative object speed also gets faster. Therefore, faster framing rate, such as 50,000 to 100,000 frames per second are required to observe the phenomenon. Due to the characteristics of the sensor, the resolution of a high-speed camera decreases when the shooting speed increases, but NAC offers an optimal high-speed camera from our versatile line-up so you can maintain higher resolutions even at faster framing rates of 50,000 frames per second or more.

Recommended cameras

- 1,280 × 896 pixel @ 54,000fps (M60)

- Further speedup in boost mode (monochrome model only)

- Monochrome ISO 100,000 Color ISO 20,000

- Up to 256GB memory and USB3.0B installed

- Small high-speed camera that can shoot up to 2,000 fps in full HD (2 million pixels)

- Approximately 62 mm square palm size that is easy to install in narrow places

- Approximately 670 g lightweight body allows coaxial shooting attached to the arm

- High sensitivity of monochrome ISO 32,000